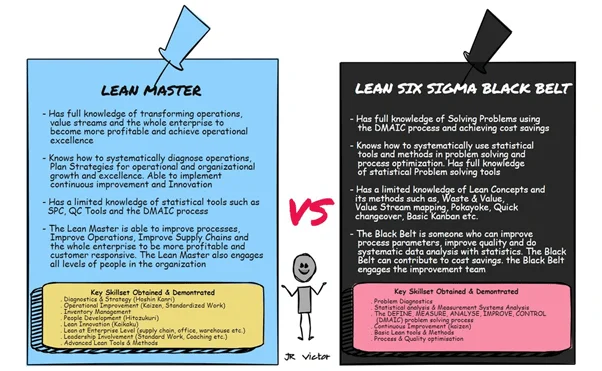

LEAN MASTER IS NOT LEAN SIX SIGMA BLACK BELT

A big confusion

which frequently happens is to assume that someone who has obtained a Lean Six Sigma Black

Belt has the full knowledge and skillset of Lean.

Having been certified as a Lean

Master and in six Sigma separately; and practicing both for clients for twenty years, I have

had the opportunity to see significant differences.

Both are powerful

methodologies. However, I see Lean as beyond an improvement methodology. Lean is more than

that. Lean is an overall organizational transformation philosophy based on the Toyota

Production System. Lean has also been ever evolving into something more holistic and

bigger.

I have created a simple infographic to point out the key differences of a

Lean Master and Lean Six Sigma Black Belt. These differences may not be there for some

people as they may have extra exposure in either of the body of knowledge beyond what the

certification process itself has taught them.

Today with more than twenty-two years of exposure on these two methodologies I use them primarily as follows with occasional sharing of tools and approaches:

LEAN PHILOSOPHIES & METHODS:

· Organizational

& Operational Strategy

· Operational Diagnostics

& Value Stream management

· Achieving

Operational Excellence

· Improving Profitability

within a brief period

· Improving Flexibility and

Customer responsiveness (Cycle Time Improvements)

· Inventory

Reduction

· Warehouse and Supply Chain

Optimization

· People engagement at all levels

SIX SIGMA DMAIC TOOLS:

· Quality Improvement

which needs statistical studies

· Systematic way of

problem solving

· Optimising parameters

· Reducing

variability in processes and input variables

· Managing

improvement projects

The Lean Master certification process is a full 5-6 months

training coupled with projects completion. This covers more than twenty methods and tools

which are not part of the Lean Six Sigma certification. Relevant statistical tools are also

taught – about 20% of what is taught in Six Sigma

The Lean Six Sigma

certification process is also a full 5-6 months of training with project completion. This

covers more than twenty statistical tools and methods not covered in Lean Masters. On the

other hand, about 20% of the tools of Lean are taught at some depth.

So, it is important to give people the right set of knowledge based on an organization’s

needs.

On our Lean Services and Lean Masters certification program. We have been

certifying Lean Masters all over Asia since 1999.

J Ramesh Victor